A chainsaw mill guide assists in converting logs into lumber by providing precise cutting guidance. It ensures that your chainsaw moves in a straight line for uniform wood planks.

Chainsaw milling can be a game-changer for woodworking enthusiasts and professionals alike. By using a guide, you can turn raw logs into valuable lumber with relative ease, right where the tree falls. This method reduces the need for expensive, heavy machinery and allows for on-site milling, saving time and transportation costs.

It’s ideal for those handling large pieces of wood who require custom thicknesses that aren’t readily available in stores. With the right knowledge and equipment, a chainsaw mill guide empowers you to make your own quality materials for construction, furniture-making, or any other wood-centric project. Remember, always prioritize safety by wearing the appropriate gear and abiding by the manufacturer’s guidelines while operating your chainsaw mill.

Understanding Chainsaw Mills

A chainsaw mill transforms a chainsaw into a portable milling machine. This tool allows you to create lumber from raw logs. You can mill on-site, which is handy for remote locations.

About Chainsaw Milling

Chainsaw milling is a method of sawing that uses a chainsaw and a milling attachment. It’s a viable alternative to large, expensive machinery.

Different Types of Chainsaw Mills

There are primarily two chainsaw mill types:

- Alaskan Mill – portable and attaches to the saw’s bar.

- Vertical Mill – handles vertical cuts, slicing stumps and logs into boards.

Pros and Cons of Chainsaw Milling

Benefits include portability, cost savings, and versatility. Limited speed and physical demand are potential downsides.

| Pros | Cons |

|---|---|

| Accessibility to remote locations | Slower than traditional mills |

| Cost-effective solution | Requires physical strength |

| Custom lumber size | Can be less precise |

Overview of Chainsaw Mill Components

Key components of a chainsaw mill include:

- Guide rails – They direct the chainsaw for straight cuts.

- Chain and bar – Important for the actual cutting.

- Depth gauge – Controls the thickness of the board.

Preparing For Chainsaw Milling

Transforming raw timber into planks of wood is thrilling, yet serious business. Before the engine roars to life and the sawdust flies, proper preparations ensure a smooth milling experience. We’ll guide you step-by-step on how to get ready for chainsaw milling.

Selecting the Right Chainsaw

The heart of chainsaw milling is the chainsaw itself. Not all chainsaws are up for this task. You need a powerful engine and a long bar. Here’s a simple checklist:

- Engine Power: At least 50cc for small jobs, 70cc or more for larger logs

- Bar Length: Match it to the width of logs you plan to mill

- Chain Type: Skip-tooth or ripping chains are best for smooth cuts

Purchasing a Chainsaw Mill Attachment

A quality chainsaw mill attachment turns your chainsaw into a portable milling machine. Choose one that’s sturdy and compatible with your chainsaw. Look for these features:

| Feature | Description |

|---|---|

| Material | Aluminum and steel last longer |

| Adjustability | Allows for different plank thicknesses |

| Portability | Lightweight designs make it easier to handle |

Safety Gear and Precautions

Your safety is paramount. Never start milling without proper gear. Wear these essentials:

- Safety Glasses: Protect your eyes from flying debris

- Hearing Protection: Protect your ears from the chainsaw’s roar

- Gloves: Improve grip and protect hands

- Chaps or Pants: Shield your legs from accidental cuts

Also, read the chainsaw’s manual. Know the emergency stop procedure.

Setting Up Your Milling Area

A well-organized milling area increases efficiency. Ensure the space is:

- Clear: Remove rocks, branches, and other hazards

- Level: A flat surface helps stabilize the log

- Spacious: Give yourself room to move safely around the log

Use saw horses or a log stand to lift the wood. This prevents your chainsaw from hitting the ground.

The Milling Process

The Milling Process is both an art and a science, requiring skill, precision, and the right equipment. In this guide, we’ll dive into the essentials of turning your chainsaw into an efficient milling machine.

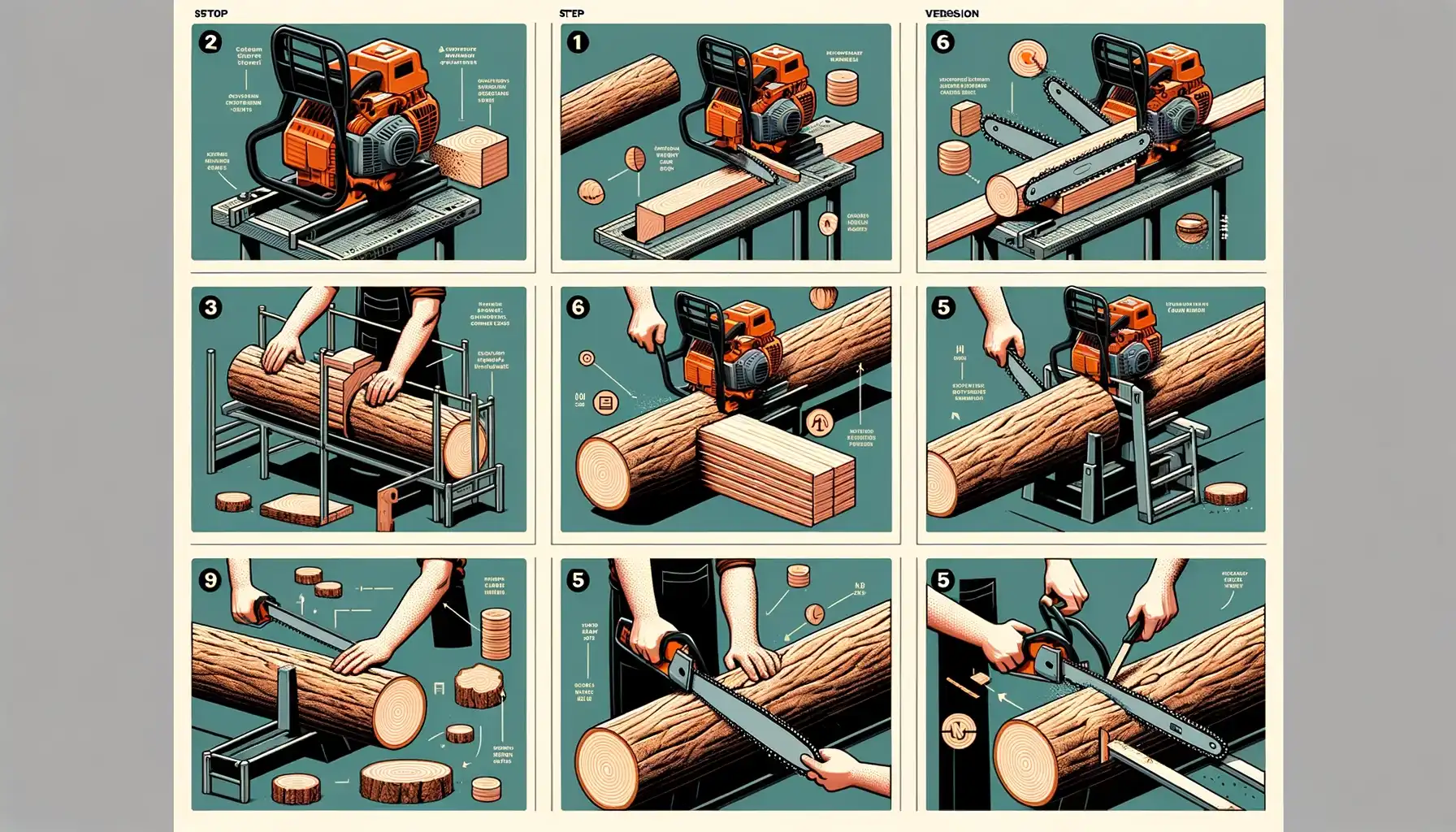

Step-by-step Guide to Chainsaw Milling

- Select the right chainsaw mill for the size of the log and the desired cut.

- Attach the chainsaw to the mill with the bar and chain securely in place.

- Set the correct depth for your first cut using the mill’s adjustable features.

- Align the mill on the log, making sure it’s parallel for a straight cut.

- Begin the cut with slow, steady pressure, keeping an eye on alignment.

- Advance the mill through the log, maintaining consistent speed and pressure.

- Repeat the process for additional cuts, adjusting the depth as needed.

Tips For Efficient Milling

- Keep the chain sharp for quicker cuts and less wear on your chainsaw.

- Use a guide rail for the first cut to ensure a flat reference surface.

- Regularly check the alignment to prevent uneven cuts.

- Oil the chain frequently to reduce friction and prevent overheating.

- Take breaks to rest and inspect the equipment for safety.

Troubleshooting Common Milling Issues

| Issue | Solution |

|---|---|

| Uneven cuts | Check the mill’s alignment and the chain’s tension. |

| Slow cutting | Sharpen the chain and ensure adequate power supply. |

| Excessive vibration | Secure all bolts and handles; balance the chainsaw in the mill. |

Maintenance and Care For Your Chainsaw Mill

Like any tool, a chainsaw mill lasts longer with proper maintenance. Clean the mill after each use to prevent sawdust build-up. Regularly inspect screws and bolts for tightness. Store the mill in a dry, covered area to reduce rust risk. Lastly, refer to your chainsaw manual for specific care and maintenance procedures to keep it running smoothly.

Maximizing Lumber Yield and Quality

Every woodworker knows that quality begins at the source. Getting the most out of your lumber starts with careful selection and milling of trees. Whether you’re a professional or a hobbyist, the right techniques can maximize yield and enhance lumber quality. Let’s explore how you can excel in this craft of transformation from tree to treasured wood.

Choosing the Right Trees and Logs

Tree selection is crucial for lumber quality. Look for healthy, straight trees with few knots. Avoid trees with signs of disease or rot. Species like oak, walnut, and cherry are often sought-after for their durable and attractive wood.

Optimal Milling Techniques For Different Wood Types

Each wood type has its quirks. Softwoods like pine require sharp blades and steady cuts to avoid tearing. Hardwoods like oak demand slower milling speeds for a smooth finish. Follow these tailored techniques to ensure the best outcome for your wood type.

Strategies to Reduce Waste

- Measure twice, cut once to ensure accuracy.

- Use thin-kerf blades to reduce sawdust.

- Optimize cutting patterns to get the most boards from each log.

Drying and Storing Milled Lumber

The drying process is vital for lumber stability. Stack milled wood properly with spacers to allow air flow. Store in a cool, dry place to prevent warping. Patience in drying yields lumber that lasts for generations.

Note: The content is SEO-optimized for ‘Chainsaw Mill Guide’ and supports users in maximizing lumber yield and quality through smart selection, milling, and processing techniques.

Advanced Chainsaw Milling Concepts

For artisans eager to take their chainsaw milling to the next level, this section delves into expert techniques and innovative adaptations that enhance precision, capability, and versatility of milling practices. Whether dealing with unusual wood shapes or integrating your mill into grand woodworking projects, advancements in this field are continuously shaping the future of milling. Unlock the potential of your chainsaw mill with these transformative ideas.

Modifications and Upgrades For Your Chainsaw Mill

Enhancing your chainsaw mill can increase efficiency and quality of the lumber produced. Consider the following upgrades:

- Better chain and bar: Invest in a high-quality ripping chain designed for efficient cutting.

- Stabilization mods: Add stabilizing bars for more precise cuts.

- Power boost: Upgrade your mill’s motor for faster milling of tougher woods.

Milling Irregular and Unique Wood Pieces

Working with irregular wood pieces requires a unique approach. Follow these tips:

| Challenge | Solution |

|---|---|

| Crooked wood: | Use guide rails to straighten the initial cut. |

| Knotty areas: | Slow down the cut to maintain blade health. |

| Variable thickness: | Adjust the depth for each pass to ensure even milling. |

Integrating Chainsaw Milling Into Larger Woodworking Projects

For projects that require multiple wood pieces or specific designs, smart milling is key. Here’s how to integrate chainsaw milling:

- Plan ahead: Visualize and sketch the project to determine the necessary lumber dimensions.

- Sequential cutting: Mill the largest pieces first to maximize wood use.

- Custom mill: Create unique lumber shapes specific to your project needs.

Future Trends in Chainsaw Milling Technology

The chainsaw milling industry is witnessing exciting technological advancements. Some trends to look out for include:

- Automation: Devices that automate cuts for uniform thickness and reduced manual labor.

- Enhanced safety features: Innovations that prioritize user safety during milling operations.

- Eco-friendly mills: Eco-designed mills aim to reduce the environmental impact.

Learn more: How to Cut Wood Slices With Chainsaw

Conclusion

Mastering the use of a chainsaw mill unlocks a world of woodworking possibilities. Remember, success hinges on selecting the right equipment and employing proper techniques. By focusing on safety and quality, your milling projects can thrive. Embrace the journey to splendid craftsmanship with every board you cut. Can’t get enough of chainsaws? Neither can we! Swing by Chainsaw Hive for your regular dose of everything chainsaw in our Knowledge area.