Common issues with the Stihl MS 661 chainsaw include starting difficulties, power loss, and operational overheating. Users also report chain tension problems and excessive vibration during use.

The Stihl MS 661 is a robust chainsaw favored by forestry professionals for its power and efficiency. Despite its popularity, certain problems can mar its performance, affecting reliability and user experience. A well-maintained MS 661 generally provides high-quality service, but it’s not uncommon for operators to encounter the aforementioned issues, necessitating troubleshooting and repair.

Understanding these challenges is crucial for maintaining the saw’s longevity and ensuring safe operation. By recognizing these potential issues, operators can take proactive measures to service and maintain their chainsaws, keeping them in peak condition and ready for demanding tasks.

The Stihl Ms 661 Chainsaw

Power, precision, and prowess define the Stihl MS 661 chainsaw. This power tool slices through wood with ease. It’s a favorite among professionals. But even the best tools have issues sometimes. This article shines a light on the MS 661’s common problems, to help you get back to cutting effectively.

Overview of the Stihl MS 661

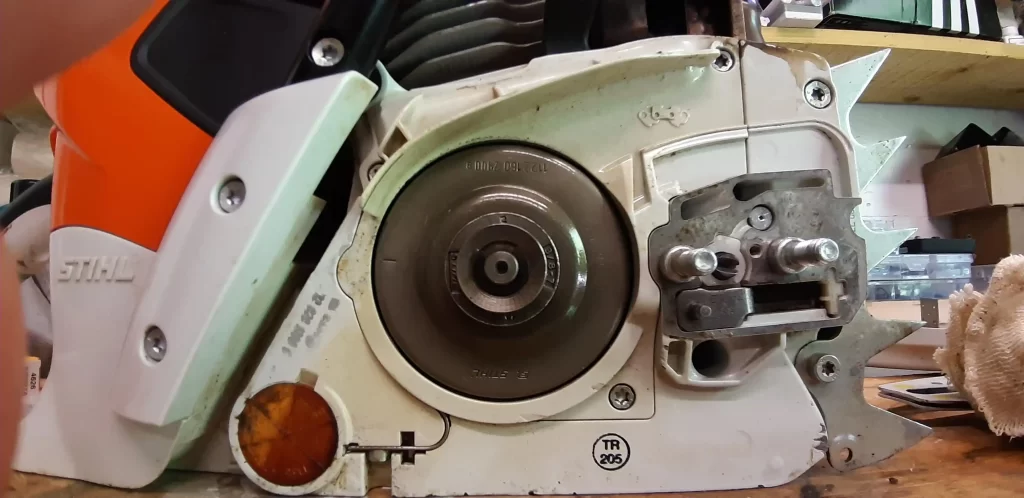

The Stihl MS 661 is a heavy-duty chainsaw designed for tough cutting tasks. It boasts a powerful engine and advanced features. Users admire its durability and efficient performance.

- Engine: Strong for big cuts.

- Bar Lengths: Various options for different jobs.

- Weight: Balanced for control.

Importance of Understanding Common Issues

Knowing problems helps to prevent damage. It ensures consistent performance. Quick fixes save time and money. This guide dives into typical Stihl MS 661 troubles for quick troubleshooting.

Purpose of the Article

This article aims to educate owners. Learn about the MS 661’s quirks and how to fix them. Gain confidence in handling this chainsaw. We’ll cover tips for maintenance and repair.

Common Performance Issues

Even robust chainsaws like the Stihl MS 661 can run into hiccups now and then. Tackling common performance issues head-on maximizes efficiency and longevity. Let’s dive into what might hamper your chainsaw’s performance.

Starting Difficulties Explained

Chainsaws should roar to life with ease. Yet, sometimes the Stihl MS 661 won’t start. This can be due to:

- Fuel mix issues: Wrong ratios can prevent starting.

- Air filter blockage: A dirty filter stops air flow.

- Spark plug problems: A bad plug denies ignition.

Power Loss During Operation

Sudden power loss is alarming during a cut. The Stihl MS 661 might lose power because of:

- Fuel system clogs: Debris in the system reduces power.

- Worn out parts: Old parts diminish engine strength.

- Chain tension: Too tight or loose impacts cutting force.

Overheating Problems and Their Causes

An overheated saw poses risks. The MS 661 gets too hot from:

- Inadequate lubrication: Friction heat damages the saw.

- Clogged cooling system: Dust and debris trap heat.

- Excessive use: Non-stop cutting causes overheating.

Mechanical Failures and Maintenance Challenges

Owners of the Stihl MS 661 chainsaw often experience mechanical issues that require keen attention. Regular maintenance can mitigate some of these challenges, ensuring the chainsaw performs effectively.

Chain Tension Issues and Bar Problems

Chain tension is vital for optimal cutting performance. Improper tension may lead to chain slippage or breakage.

- Check tension regularly.

- Adjust using the tensioning screw if needed.

- Maintain the bar’s condition to prevent uneven wear.

Bar issues may arise from bent or damaged bars. Inspect frequently for signs of damage or wear.

Air Filtration and Clogging Concerns

The MS 661’s air filtration system is crucial in preventing engine damage from debris. A clogged air filter inhibits performance.

- Clean or replace air filters routinely.

- Ensure seals are intact to avoid debris entry.

- Check the air intake for any obstruction.

Fuel System Complications

Fuel system issues can stall the chainsaw. Contaminated fuel or a faulty carburetor can cause starting problems.

- Use clean, fresh fuel to avoid contamination.

- Inspect the carburetor for signs of malfunction.

- Regularly clean the fuel filter and replace when necessary.

Troubleshooting Guide For the Ms 661

Experiencing issues with your Stihl MS 661 chainsaw can be frustrating. But fear not, for our ‘Troubleshooting Guide for the MS 661’ offers practical steps to get your chainsaw back in action. Let’s uncover common problems and their fixes to keep your tool running smoothly.

Step-by-step Diagnosis Process

Follow these steps to pinpoint the issue:

- Check the fuel. Ensure it’s fresh and properly mixed.

- Inspect the spark plug. Look for damage or buildup.

- Examine the air filter. Clean or replace if dirty.

- Review the carburetor. It may need adjustment.

- Test the ignition system. Verify if it’s creating a spark.

- Assess the compression. Low compression indicates engine issues.

Solutions For Recurring Problems

Common challenges and quick solutions:

| Issue | Solution |

|---|---|

| Won’t Start | Replace spark plug, check fuel mix. |

| Poor Cutting Performance | Sharpen chain, adjust tension. |

| Overheating | Clean cooling fins, check oil levels. |

| Stalling | Clean air filter, adjust carburetor. |

When to Seek Professional Help

Some problems need an expert’s touch. Recognize these signs:

- Persistent issues after following the guide.

- Engine compression problems detected.

- Complex carburetor troubles or adjustments.

- Major engine damage, uncommon noises.

Contact a certified Stihl technician if these occur.

Preventative Measures and Best Practices

Keeping your Stihl MS 661 chainsaw running smoothly requires attention to detail. We’ll dive into how to maintain your powerhouse tool. By following preventative measures and best practices, you can avoid common issues and extend its lifespan.

Routine Maintenance Tips

Clean after each use to prevent buildup. Replacing the air filter regularly is vital for engine health. Check the spark plug for deposits and wear. Sharpen the chain to ensure efficient cutting. Inspect the guide bar for damage or wear. These steps will keep your MS 661 performing its best.

- Cleaning sawdust and debris.

- Replacing filters and spark plugs as needed.

- Sharpening the chain for peak performance.

- Checking the guide bar for smooth operation.

Proper Usage to Reduce Wear and Tear

Operate your Stihl MS 661 within its limits. Avoid cutting materials not meant for the chainsaw. Use the correct fuel-oil mixture for optimal engine performance. Follow the manual’s recommendations on operation. Handling the chainsaw correctly can vastly reduce potential problems.

- Following operating limits.

- Using the right materials and fuel.

- Adhering to the user manual’s guidance.

Long-term Storage Recommendations

Prevent issues after long-term storage. Drain the fuel tank and run the engine dry before storing. Apply oil to the chain and bar to protect against rust. Store the chainsaw in a clean, dry place. By doing this, you ensure it’s ready for action when you are.

| Action | Reason |

|---|---|

| Drain Fuel | Prevents carburetor clogging |

| Lube Chain | Protects against rust |

| Dry Storage | Keeps components moisture-free |

Learn more: Stihl MS 361 Problems

User Experiences and Professional Opinions

We’re slicing into the performance of this powerhouse, examining what users say about its capabilities and any issues they might face, as well as evaluating expert analyses on its reliability. Let’s cut through the noise and see how the MS 661 holds up against its competitors.

Testimonials From Ms 661 Users

Many MS 661 owners rave about the saw’s raw power and durability for heavy-duty tasks. However, some users point out concerns:

- Starting difficulties – Occasional hard starts have been a frustration.

- Weight – For some, the saw is heavy and demands frequent breaks during work.

- Fuel Efficiency – Mixed feedback reveals a split; some find it efficient, others do not.

Expert Reviews on Reliability and Performance

Reliability and performance under the microscope present an interesting view:

| Aspect | Expert Opinion |

|---|---|

| Power Output | Consistently high marks for impressive performance in demanding settings. |

| Maintenance | Noted as straight forward; routine maintenance keeps it in top shape. |

| Longevity | Common sentiment that, with proper care, the MS 661 is a long-term companion. |

Comparison With Other Models in the Same Category

Stacking up the MS 661 against its peers reveals its standing in a competitive field. Key comparison points include:

- Power-to-weight ratio surpasses many models. Offers strength without the bulk.

- Price is on the higher end. Its features justify the cost for most professionals.

- Accessibility of parts and service. Stihl’s widespread network eases maintenance worries.

FAQs of Stihl Ms 661 Problems

What Are Common Reasons Stihl Chainsaw Won’t Start?

Common reasons a Stihl chainsaw won’t start include a flooded engine, old fuel, a dirty air filter, a defective spark plug, or a clogged carburetor. Regular maintenance can prevent these issues.

Why Is My Chainsaw Hard to Start?

A chainsaw might be hard to start due to a dirty air filter, stale fuel, a clogged carburetor, or a faulty spark plug. Regular maintenance and timely check-ups can prevent such issues.

How Do You Run a Stihl Chainsaw?

To run a Stihl chainsaw, start by engaging the chain brake. Press the decompression valve, if available. Place the saw on stable ground and firmly hold it. Pull the starting cord sharply. Release the chain brake before cutting. Always ensure proper safety gear is worn.

What Are Common Stihl Ms 661 Issues?

Stihl MS 661 chainsaws may experience starting difficulties, power loss, bar oil leakage, or carburetor problems.

Conclusion

Navigating the world of chainsaw maintenance can be tricky, but being informed helps immensely. Our exploration of the Stihl MS 661’s common issues hopefully arms you with practical solutions. Remember, regular care and timely repairs can extend your equipment’s life.

For more tool tips and guides, stay connected to our blog. Keep your chainsaw running smoothly and your projects on track. Turn your chainsaw passion into expertise with Chainsaw Hive. Our Knowledge section is your go-to resource!